Loading AI tools

Family of submachine guns From Wikipedia, the free encyclopedia

The STEN (or Sten gun) is a British submachine gun chambered in 9×19mm which was used extensively by British and Commonwealth forces throughout World War II and during the Korean War. The Sten paired a simple design with a low production cost, facilitating mass production to meet the demand for submachine guns.

| Sten submachine gun | |

|---|---|

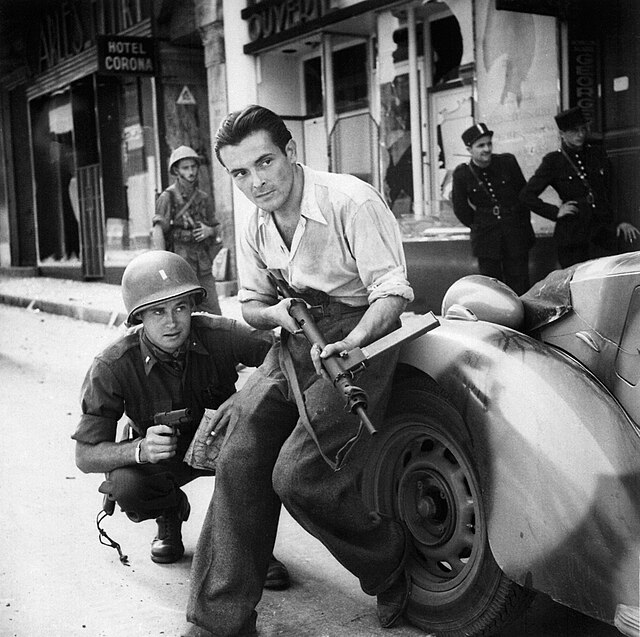

A Sten MK II | |

| Type | Submachine gun |

| Place of origin | United Kingdom |

| Service history | |

| In service | 1941–1960s (United Kingdom) 1941–present (Other countries) |

| Used by | See Users |

| Wars | World War II Second Sino-Japanese War Chinese Civil War Indonesian National Revolution[1] First Indochina War Indo-Pakistan Wars 1948 Arab–Israeli War Malayan Emergency Korean War Mau Mau Uprising[2] Algerian War[3] Suez Crisis Sino-Indian War Vietnam War Indonesia–Malaysia confrontation[4] Laotian Civil War Greek Civil War[5] Bangladesh Liberation War[6] Lebanese Civil War Angolan Civil War Rhodesian Bush War Turkish invasion of Cyprus IRA Border Campaign The Troubles Punjab insurgency Maluku sectarian conflict[7] Iraq War[8] Syrian Civil War[9] |

| Production history | |

| Designer | Major Reginald V. Shepherd Harold J. Turpin |

| Designed | 1940 |

| Manufacturer | Royal Small Arms Factory Enfield BSA ROF Fazakerley ROF Maltby ROF Theale Berkshire Lines Brothers Ltd Long Branch Arsenal, Canada[a] Various underground resistance group factories |

| Unit cost | £2 6s in 1942 |

| Produced | 1941– (version dependent) |

| No. built | 3.7–4.6 million (all variants, depending on source) |

| Variants | Mk. I, II, IIS, III, IV, V, VI |

| Specifications | |

| Mass | 3.2 kg (7.1 lb) (Mk. II) |

| Length | 762 mm (30.0 in) |

| Barrel length | 196 mm (7.7 in) |

| Cartridge | 9×19mm Parabellum |

| Action | Blowback-operated, open bolt |

| Rate of fire | version dependent; ~500–600 round/min |

| Muzzle velocity | 365 m/s (1,198 ft/s) 305 m/s (1,001 ft/s) (suppressed models) |

| Effective firing range | 60 m (66 yd)[10] |

| Feed system | 32-round detachable box magazine |

| Sights | fixed peep rear, post front |

As well as equipping regular units, the Sten was distributed to resistance groups within occupied Europe. Its simple design made it an effective insurgency weapon for resistance groups.

The Sten is a select fire, blowback-operated weapon with a side-mounted magazine. Sten is an acronym, derived from the names of the weapon's chief designers: Major Reginald V. Shepherd and Harold J. Turpin, and "En" for the Enfield factory.[11][b] Around four million Stens in various versions were made in the 1940s, making it the second most produced submachine gun of the Second World War, after the Soviet PPSh-41. The Sten served as the basis for the Sterling submachine gun, which replaced the Sten in British service from the 1950s.

The Sten emerged while Britain was engaged in the Battle of Britain, facing invasion by Germany. The army was forced to replace weapons lost during the evacuation from Dunkirk while expanding their arsenal at the same time. After the start of the war and to 1941 (and even later), the British purchased all the Thompson submachine guns they could from the United States, but these did not meet demand, and Thompsons were expensive, the M1928 costing $200 in 1939 (and still $70 in 1942), whereas a Sten would turn out to cost only $11.[14] American entry into the war at the end of 1941 placed an even bigger demand on the facilities making Thompsons. In order to rapidly equip a sufficient fighting force to counter the Axis threat, the Royal Small Arms Factory, Enfield, was commissioned to produce an alternative.

The credited designers were Major R. V. Shepherd, OBE, Inspector of Armaments in the Ministry of Supply Design Department at The Royal Arsenal, Woolwich, (later Assistant Chief Superintendent at the Armaments Design Department) and Harold John Turpin, Senior Draughtsman of the Design Department of the Royal Small Arms Factory (RSAF), Enfield. Shepherd had been recalled to service after having retired and spending some time at the Birmingham Small Arms Company (BSA).

The Sten shared design features, such as its side-mounted magazine configuration, with the Lanchester submachine gun being produced at the same time for the Royal Navy and Royal Air Force, which was a copy of the German MP28. In terms of manufacture, the Lanchester was entirely different, being made of high-quality materials with pre-war fit and finish, in stark contrast to the Sten's austere execution. The Lanchester and Sten magazines were even interchangeable (though the Lanchester's magazine was longer with a 50-round capacity, compared to the Sten's 32.)[15]

The Sten used simple stamped metal components and minor welding, which required minimal machining and manufacturing. Much of the production could be performed by small workshops, with the firearms assembled at the Enfield site. Over the period of manufacture, the Sten design was further simplified: the most basic model, the Mark III, could be produced from five man-hours of work.[16] Some of the cheapest versions were made from only 47 different parts (out of 47 components, only the barrel and bolt were machined).[17] The Mark I was a more finely finished weapon with a wooden foregrip and handle; later versions were generally more spartan, although the final version, the Mark V, which was produced after the threat of invasion had died down, was produced to a higher standard.

The Sten underwent various design improvements over the course of the war. For example, the Mark 4 cocking handle and corresponding hole drilled in the receiver were created to lock the bolt in the closed position to reduce the likelihood of unintentional discharges inherent in the design. Most changes to the production process were more subtle, designed to give greater ease of manufacture and increased reliability, and the potentially great differences in build quality contributed to the Sten's reputation as being an unreliable weapon. However, a 1940 report stated that "Exaggerated reports about the unreliability [of the Sten] were usually related to the quality of manufacture. Don Handscombe and his comrades in the Thundersley Patrol of the Auxiliary Units rated them more reliable than the Thompson SMG."[18] Sten guns of late 1942 and beyond were highly effective weapons, though complaints of accidental discharge continued throughout the war.

The Sten was replaced by the Sterling submachine gun from 1953 and was gradually withdrawn from British service in the 1960s. Other Commonwealth nations followed suit, either by creating their own replacements or adopting foreign designs.

The Sten was a blowback-operated submachine gun firing from an open bolt with a fixed firing pin on the face of the bolt. This means the bolt remains to the rear when the weapon is cocked and on pulling the trigger the bolt moves forward from spring pressure, stripping the round from the magazine, chambering it and firing the weapon all in the same movement. There is no breech locking mechanism; the rearward movement of the bolt caused by the recoil impulse is arrested only by the mainspring and the bolt's inertia.

The German MP40, Russian PPSh-41, and US M3 submachine gun, among others, used the same operating mechanisms and design philosophy of the Sten, namely their low cost and ease of manufacture. Though the MP40 was also built largely for this purpose, Otto Skorzeny went on record saying that he preferred the Sten because it required less raw material to produce and performed better under adverse combat conditions.[19] The effect of putting lightweight automatic weaponry into the hands of soldiers greatly increased the short-range firepower of the infantry, especially when the main infantry weapon was a bolt-action rifle capable of only around 15 rounds per minute and not suited for short-range combat.[citation needed] The open-bolt firing mechanism, short barrel and use of pistol ammunition severely restricted accuracy and stopping power, with an effective range of only around 60 m (200 ft), compared to 500 m (1,600 ft) for the Lee–Enfield rifle.

Stoppages could occur for poor maintenance, while others were particular to the Sten. Carbon build up on the face of the breech or debris in the bolt raceway could cause a failure to fire, while a dirty chamber could cause a failure to feed.[20] Firing the Sten by grasping the magazine with the supporting hand, contrary to instruction, tended to wear the magazine catch, altering the angle of feed and causing a failure to feed; the correct method of holding the weapon was as with a rifle, the left hand cradling the fore piece.

The Sten's magazine, which, like the Lanchesters, derived from the MP28, originally to use its magazines, which incorporated the faults of the MP28 magazine.[21] The magazine had two columns of 9mm cartridges in a staggered arrangement, merging at the top to form a column. While other staggered magazines, such as the Thompson, fed from the left and right side alternately (known as "double column, double feed"), the Sten magazine required the cartridges gradually to merge at the top of the magazine to form a column ("double column, single feed"). Dirt or foreign matter in this taper area could cause feed malfunctions. The walls of the magazine lip had to endure the full stresses of the rounds being pushed in by the spring. This, along with rough handling could result in deformation of the magazine lips (which required a precise 8° feed angle to operate), resulting in misfeeding and a failure to fire.[c] If a Sten failed to feed due to jammed cartridges in the magazine, standard practice to clear it was to remove magazine from the gun, tap the base of the magazine against the knee, re-insert the magazine, then re-cock the weapon and fire again as normal.[20] To facilitate easier loading when attempting to push the cartridges down to insert the next one, a magazine filler tool was developed and formed part of the weapon's kit. The slot on the side of the body where the cocking knob ran was also a target of criticism, as the long opening could allow foreign objects to enter. On the other hand, a beneficial side-effect of the Sten's minimalist design was that it would fire without any lubrication.[20] This proved useful in desert environments such as the Western Desert campaign, where lubricating oil retained dust and sand.[citation needed]

The selector was a push button type that actuated a sear disconnector to enable firing in semi-automatic. When firing in this mode, the bolt moves rearward tripping on the sear disconnector downwards requiring the user to release the trigger to fire the weapon again. When firing in full automatic, the selector slightly pivots and moves the sear disconnector sideways enabling the trigger to hold the sear in the firing position without interference of the bolt movement. The open bolt design combined with cheap manufacture and rudimentary safety devices also meant the weapon was prone to accidental discharges, which proved hazardous. A simple safety could be engaged while the bolt was in the rearwards (cocked) position. However, if a loaded Sten with the bolt in the closed position was dropped, or the butt was knocked against the ground, the bolt could move far enough rearward to pick up a round (but not far enough to be engaged by the trigger mechanism) and the spring pressure could be enough to chamber and fire the round. The Mk. IV's cocking handle was designed to prevent this by enabling the bolt to be locked in its forward position, immobilising it. Wear and manufacturing tolerances could render these safety devices ineffective. Though the Sten was somewhat prone to malfunction, in the hands of a well-trained soldier, who knew how to avoid the Sten's failings, they were less of a liability as otherwise may be suggested. According to Leroy Thompson, "Troops usually made the conscious choice to keep the Sten with a magazine in place, based on the assumption that they might need it quickly. It might, then, be argued that more troops were saved by having their Sten ready when an enemy was suddenly encountered than were injured by accident. The Sten was more dangerous to its users than most infantry weapons, but all weapons are dangerous".[19]

Sten guns were produced in several basic marks, of which nearly half of the total produced consisted of the Mark II variant. Approximately 4.5 million Stens were produced during the Second World War.[22]

The first ever Mk I Sten gun (number 'T-40/1' indicating its originator Harold Turpin, the year 1940 and the serial number "1") was handmade by Turpin at the Philco Radio works at Perivale, Middlesex during December 1940/January 1941 in 36 days.[23] This particular weapon is held by the historical weapons collection of the British Army's Infantry and Small Arms School Corps in Warminster, Wiltshire.[24]

The Mark I had a conical flash hider and fine finish. The bolt on the Mark I rotated downwards to hold open for safety, similar to that of a bolt action rifle (The bolt on Mark II+ variants rotate upwards). The handguard, vertical forward grip and some of the stock were made of wood. The stock consisted of a small tube, similar to the Mark II Canadian. The barrel shroud had vent holes. The magazine insert was fixed to the receiver with screws (unlike the later found on Mark II+ variants that could be rotated 90 degrees for stowage). A design choice that was only present on the Mark I was that the vertical forward grip could be rotated forward to make it easier to stow. 100,000 Mark I Stens were made before production was moved to the Mark II. Mark I Stens in German possession were designated MP 748(e), the 'e' standing for englisch.[25]

The Mark I* (pronounced "Mark-One-Star") variant was to simplify production of the Mark I, the handguard, vertical foreward grip, vent holes, wooden furniture and conical flash hider were removed with this variant.[26][25] It was the first variant to come with a tube stock.

The Mark II was the most common mainstream variant, with two million units produced.[22] The flash eliminator and the folding handle (the grip) of the Mk I were omitted. A removable barrel was now provided which projected 3 inches (76 mm) beyond the barrel sleeve. It used a tube stock. Also, a special catch allowed the magazine to be slid partly out of the magazine housing and the housing rotated 90 degrees counter-clockwise (from the operator's perspective), together covering the ejection opening and allowing the weapon and magazine both to lie flat on its side.[25]

The barrel sleeve was shorter and rather than having small holes on the top, it had three sets of three holes equally spaced on the shroud. To allow a soldier to hold a Sten by the hot barrel sleeve with the supporting hand, an insulating lace-on leather sleeve guard was sometimes issued.[d] Sten Mk II's in German possession were designated MP 749(e). Some Mk IIs had wooden stocks.[25] The Spz-kr assault rifle, a rudimentary German design made in the closing stages of the war, used the receiver and components from the Sten Mk II, and the MP 3008 was made as a cheap copy.

During World War II, a variation of the Sten gun was produced at the Long Branch Arsenal plant in Long Branch, Ontario (now Lakeview, an area of Mississauga, Peel Region). This was very similar to the regular Mark II, with a different stock ('skeleton' type instead of strut type). It was first used in combat in the Dieppe Raid in 1942.

The Mark II that were made in China with a copy known as the M38.[27] The Chinese M38s were made in an automatic-only configuration, unlike the standard Mark II. The M38 was made in 9×19mm and 7.62×25mm Tokarev variants.

After the Mark II, this was the most produced variant of the Sten, manufactured in Canada alongside the United Kingdom, with Lines Bros Ltd being the largest producer.[25] The Mark III was made of 48 parts, compared to the Mark II's 69, but the Mark II remained more commonplace for logistical reasons – parts between the two were not interchangeable.[16] Though slightly lighter, the magazine well was fixed in place, and the barrel could not be removed, meaning if it was damaged the weapon had to be scrapped. Combined with the fact the Mark III was more prone to failure than the Mark II, production of the weapon ceased in September 1943.[28] Unlike the Mark II, the receiver, ejection port, and barrel shroud were unified, leading to them being extended further up the barrel. Captured Sten Mk III's in German possession were designated MP 750(e). A total of 876,886 Mark III's were produced.[29]

The Mark V added a bayonet mount, and a wooden pistol grip and stock.[25] There was a No. 4 Lee–Enfield Front sight and the weapon was of better quality manufacture and finish than the Mk II and Mk III.

Another variant of the Mk V had a swivel stock and rear sight mirror intended for firing around corners in urban warfare, similar to the Krummlauf developed by the Germans for the StG 44.

Mk II(S) and Mk VI models incorporated an integral suppressor and had a lower muzzle velocity than the others due to a ported barrel intended to reduce velocity to below the speed of sound – 305 m/s (1,001 ft/s) – without needing special ammunition. The suppressor heated up rapidly when the weapon was fired, and a canvas cover was laced around the suppressor for protection for the firer's supporting hand.[30]

The suppressed models were produced at the request of the Special Operations Executive (SOE) for use in clandestine operations in occupied Europe, starting with the Mk II(S) in 1943. Owing to their tendency to overheat, they were fired in short bursts or single shots.[31] Some guns were even changed to semi-automatic only.

In addition to its use in the European theatre, the Mk II(S) saw service with clandestine units in the Southwest Pacific Area (SWPA) such as the Services Reconnaissance Department and SOE's Force 136 on operations against the Imperial Japanese Army. The Sten Mk II(S) was used by the Operation Jaywick party during their raid into Japanese-occupied Singapore Harbour.

The Sten Mk II(S) also saw service with the Special Air Service Regiment during the Vietnam War.

The Sten MKII can be converted to take 7.62×25mm ammo by changing the barrel, magazine, magazine housing and bolt.[50] Some of them were imported to the US before 1968.[50] These MKIIs were made by Long Branch as part of a Nationalist Chinese contract.[51]

While all types of 7.62×25mm ammo can be used, those made in the former Czechoslovakia are made for small arms that can handle high velocity, so users are not advised to use them.[50]

The Sten, especially the Mark II, tended to attract affection and loathing in equal measure. Its peculiar appearance when compared to other firearms of the era, combined with sometimes questionable reliability made it unpopular with some front-line troops.[52] It gained nicknames such as "Plumber's Nightmare", "Plumber's Abortion", or "Stench Gun".[22] The Sten's advantage was its ease of mass-production manufacture in a time of shortage during a major conflict.

Made by a variety of manufacturers, often with subcontracted parts, some early Sten guns were made poorly and/or not to specification, and could malfunction in operation, sometimes in combat.[53] The double-column, single-feed magazine copied from the German MP28 was never completely satisfactory, and hasty manufacturing processes often exacerbated the misfeed problems inherent in the design. A common statement heard from British forces at the time was that the Sten was made "by Marks and Spencer out of Woolworth."[54] British and Commonwealth forces in the early years of the war often extensively test-fired their weapons in training to weed out bad examples; a last-minute issue of newly manufactured Stens prior to going into action was not welcomed.[citation needed]

The MK II and III Stens were regarded by many soldiers as very temperamental, and could accidentally discharge if dropped or even laid on the ground whilst the gun was cocked.[54] Others would fire full-automatic when placed on 'single', or fire single shots when placed on 'automatic'.[54] This was particularly true of early Stens using bronze bolts, where the sear projection underneath the bolt could wear down more easily than ones made of case-hardened steel.

Stens could jam at inopportune moments. One of the more notable instances of this was the assassination of SS–Obergruppenführer Reinhard Heydrich on 27 May 1942, when Czechoslovak Warrant Officer Jozef Gabčík wanted to fire his Sten point blank at Heydrich, only to have it misfire. His comrade Jan Kubiš then hastily tossed a grenade, which mortally wounded Heydrich.[53] There are other accounts of the Sten's unreliability, some of them true, some exaggerated and some apocryphal. France[55] manufactured (well-made) Sten copies postwar into the early 1950s, evidently believing in the basic reliability and durability of the design.

A well-maintained (and properly functioning) Sten gun was a devastating close-range weapon for sections previously armed only with bolt-action rifles. In addition to regular British and Commonwealth military service, Stens were air-dropped in quantity to resistance fighters and partisans throughout occupied Europe. Due to their slim profile and ease of disassembly/reassembly, they were good for concealment and guerrilla warfare. Wrapping the barrel in wet rags would delay undesirable overheating of the barrel.[56] Guerrilla fighters in Europe became adept at repairing, modifying and eventually scratch-building clones of the Sten (over 2,000 Stens and about 500 of the similar Błyskawica SMGs were manufactured in occupied Poland).

Canadian infantry battalions in northwest Europe retained spare Sten guns for special missions and the Canadian Army reported a surplus of the weapons in 1944. The Sten saw use even after the economic crunch of World War II, replacing the Royal Navy's Lanchester submachine guns into the 1960s, and was used in the Korean War, including specialist versions for British Commandos. It was slowly withdrawn from British Army service in the 1960s and replaced by the Sterling SMG; Canada also phased out the Sten, replacing it with the C1 SMG.

The Sten was one of the few weapons that the State of Israel could produce domestically during the 1948 Arab–Israeli War. Even before the declaration of the State of Israel, the Yishuv had been producing Stens for the Haganah; after the declaration, Israel continued making Stens for IDF use. The opposing side also used (mostly British-made) Stens, particularly the irregular and semi-regular Arab Liberation Army.[57]

In the 1950s, "L numbering" came into use in the British Army for weapons—Stens were then known as L50 (Mk II), L51 (Mk III) and L52 (Mk V).

One of the last times the Sten was used in combat during British service was with the RUC during the IRA border campaign of 1956–1962. In foreign service, the Sten was used in combat at least as recently as the Indo-Pakistani War of 1971.

Sten guns were widely used by guerrilla fighters during the 1971 Bangladesh Liberation War.[58] In 1975, President Sheikh Mujibur Rahman and his family members were assassinated using Sten guns.[59]

A number of suppressed Stens were in limited use by the US Special Forces during the Vietnam War, including c. 1971, by the United States Army Rangers.[60]

In 1984, Indian prime minister Indira Gandhi was assassinated by two of her bodyguards, one of whom fired the entire magazine (30 rounds) of his Sten at point-blank range, of which 27 hit her.

In the Second Sino-Japanese War and the Chinese Civil War, both nationalists and communist Chinese forces used the Sten. Some Stens were converted by the communists to 7.62×25mm[27] by using the magazine housing from a PPS to accept curved PPS magazines. British, Canadian, and Chinese Stens were seen in the hands of the communists during the Korean and Vietnam Wars.[27]

The Finnish Army acquired moderate numbers of Stens in the late 1950s, mainly Mk. III versions. Refurbishment at the Kuopio Arsenal included bluing of the arms. Stens in Finnish service saw limited usage by conscripts (notably combat swimmers) and were mostly stockpiled for use in a future mobilization.

During the Zapatista movement in 1994, some Zapatista soldiers were armed with Sten guns.[61]

Seamless Wikipedia browsing. On steroids.

Every time you click a link to Wikipedia, Wiktionary or Wikiquote in your browser's search results, it will show the modern Wikiwand interface.

Wikiwand extension is a five stars, simple, with minimum permission required to keep your browsing private, safe and transparent.