Battery energy storage system

Energy storage system using electrochemical secondary cells From Wikipedia, the free encyclopedia

A battery energy storage system (BESS), battery storage power station, battery energy grid storage (BEGS) or battery grid storage is a type of energy storage technology that uses a group of batteries in the grid to store electrical energy. Battery storage is the fastest responding dispatchable source of power on electric grids, and it is used to stabilise those grids, as battery storage can transition from standby to full power in under a second to deal with grid contingencies.[1]

Battery energy storage systems are generally designed to be able to output at their full rated power for several hours. Battery storage can be used for short-term peak power[2] and ancillary services, such as providing operating reserve and frequency control to minimize the chance of power outages. They are often installed at, or close to, other active or disused power stations and may share the same grid connection to reduce costs. Since battery storage plants require no deliveries of fuel, are compact compared to generating stations and have no chimneys or large cooling systems, they can be rapidly installed and placed if necessary within urban areas, close to customer load, or even inside customer premises.

As of 2021, the power and capacity of the largest individual battery storage system is an order of magnitude less than that of the largest pumped-storage power plants, the most common form of grid energy storage. For example, the Bath County Pumped Storage Station, the second largest in the world, can store 24 GWh of electricity and dispatch 3 GW while the first phase of Vistra Energy's Moss Landing Energy Storage Facility can store 1.2 GWh and dispatch 300 MW.[3] However, grid batteries do not have to be large — a high number of smaller ones (often as hybrid power) can be widely deployed across a grid for greater redundancy and large overall capacity.

As of 2019, battery power storage is typically cheaper than open cycle gas turbine power for use up to two hours, and there was around 365 GWh of battery storage deployed worldwide, growing rapidly.[4] Levelized cost of storage (LCOS) has fallen rapidly. From 2014 to 2024, cost halving time was 4.1 years.[5] The price was US$150 per MWh in 2020,[6][7][8] and further reduced to US$117 by 2023.[9]

Construction

Summarize

Perspective

Battery storage power plants and uninterruptible power supplies (UPS) are comparable in technology and function. However, battery storage power plants are larger.

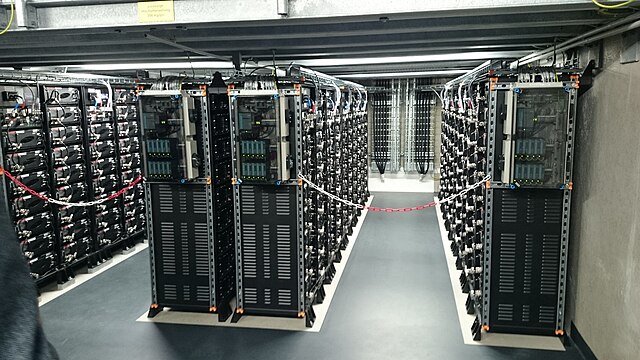

For safety and security, the actual batteries are housed in their own structures, like warehouses or containers. As with a UPS, one concern is that electrochemical energy is stored or emitted in the form of direct current (DC), while electric power networks are usually operated with alternating current (AC). For this reason, additional inverters are needed to connect the battery storage power plants to the high voltage network. This kind of power electronics include gate turn-off thyristor, commonly used in high-voltage direct current (HVDC) transmission.

Various accumulator systems may be used depending on the power-to-energy ratio, the expected lifetime and the costs. In the 1980s, lead-acid batteries were used for the first battery-storage power plants. During the next few decades, nickel–cadmium and sodium–sulfur batteries were increasingly used.[12] Since 2010, more and more utility-scale battery storage plants rely on lithium-ion batteries, as a result of the fast decrease in the cost of this technology, caused by the electric automotive industry. Lithium-ion batteries are mainly used. A 4-hour flow vanadium redox battery at 175 MW / 700 MWh opened in 2024.[13] Lead-acid batteries are still used in small budget applications.[14]

Safety

Summarize

Perspective

Most of the BESS systems are composed of securely sealed battery packs, which are electronically monitored and replaced once their performance falls below a given threshold. Batteries suffer from cycle ageing, or deterioration caused by charge–discharge cycles. This deterioration is generally higher at high charging rates and higher depth of discharge. This aging cause a loss of performance (capacity or voltage decrease), overheating, and may eventually lead to critical failure (electrolyte leaks, fire, explosion). Sometimes battery storage power stations are built with flywheel storage power systems in order to conserve battery power.[15] Flywheels may handle rapid fluctuations better than older battery plants.[16]

BESS warranties typically include lifetime limits on energy throughput, expressed as number of charge–discharge cycles.[17]

Lead-acid based batteries

Lead-acid batteries are first generation batteries are generally used in older BESS systems.[18] Some examples are 1.6 MW peak, 1.0 MW continuous battery was commissioned in 1997.[19] Compared to modern rechargeable batteries, lead-acid batteries have relatively low energy density. Despite this, they are able to supply high surge currents. However, non-sealed lead-acid batteries produce hydrogen and oxygen from the aqueous electrolyte when overcharged. The water has to be refilled regularly to avoid damage to the battery; and, the inflammable gases have to be vented out to avoid explosion risks. However, this maintenance has a cost, and recent batteries such as Li-ion batteries do not have such an issue.

Lithium based batteries

Lithium-ion batteries are designed to have a long lifespan without maintenance. They generally have high energy density and low self-discharge.[20] Due to these properties, most modern BESS are lithium-ion-based batteries.[21]

A drawback of some types of lithium-ion batteries is fire safety, mostly ones containing cobalt.[22] The number of BESS incidents has remained around 10–20 per year (mostly within the first 2–3 years of age), despite the large increase in number and size of BESS. Thus failure rate has decreased. Failures occurred mostly in controls and balance of system, while 11% occurred in cells.[23]

Examples of BESS fire accidents include individual modules in 23 battery farms in South Korea in 2017 to 2019,[24] a Tesla Megapack in Geelong,[25][26] the fire and subsequent explosion of a battery module in Arizona,[23] and the cooling liquid short circuiting incidents and fire at the Moss Landing LG battery.[27][28][29]

This resulted in more research in recent years for mitigation measures for fire safety.[30]

By 2024, the lithium iron phosphate (LFP) battery has become another significant type for large storages due to the high availability of its components, longer lifetime and higher safety compared to nickel-based Li-ion chemistries.[31] An LFP-based energy storage system that was installed in Paiyun Lodge on Mt. Jade (Yushan) (the highest alpine lodge in Taiwan) and operated since 2016, has, as of 2024, operated without a safety incident.[32]

Sodium-based batteries

Alternatively, sodium-based batteries are materials that are increasingly for BESS utilisation. Compared to lithium-ion batteries, sodium-ion batteries have somewhat lower cost, better safety characteristics, and similar power delivery characteristics. However it has a lower energy density compared to lithium-ion batteries. Its working principle and cell construction are similar to those of lithium-ion battery (LIB) types, but it replaces lithium with sodium as the intercalating ion. Some sodium-based batteries can also operate safely at high temperatures (sodium–sulfur battery). Some notable sodium battery producers with high safety claims include (non-exclusive) Altris AB, SgNaPlus and Tiamat. Sodium-based batteries are not fully commercialised yet. The largest BESS utilizing sodium-ion technology started operating in 2024 in Hubei province, boasts a capacity of 50 MW / 100 MWh.[33]

Operating characteristics

Summarize

Perspective

Since they do not have any mechanical parts, battery storage power plants offer extremely short control times and start times, as little as 10 ms.[34] They can therefore help dampen the fast oscillations that occur when electrical power networks are operated close to their maximum capacity or when grids suffer anomalies. These instabilities – fluctuations with periods of as much as 30 seconds – can produce peak swings of such amplitude that they can cause regional blackouts. Some of the parameters are voltage, frequency and phase. A properly sized battery storage power plant can efficiently counteract these oscillations; therefore, applications are found primarily in those regions where electrical power systems are operated at full capacity, leading to a risk of instability.[citation needed] However, some batteries have insufficient control systems, failing during moderate disruptions they should have tolerated.[35] Batteries are also commonly used for peak shaving for periods of up to a few hours.[2] A more recent use is strengthening transmission, as long power lines can be operated closer to their capacity when batteries handle the local difference between supply and demand.[36]

Storage plants can also be used in combination with an intermittent renewable energy source in stand-alone power systems.[37]

Largest grid batteries

| Name | Commissioning date | Energy (MWh) | Power (MW) | Duration (hours) | Type | Country | Location/coords | Refs |

|---|---|---|---|---|---|---|---|---|

| Edwards Sanborn | 2022-2024 | 3287 | Lithium-ion | United States | [38][39][40][41] | |||

| Bisha | 2025 | 2000 | 500 | 4 | Lithium-ion | Saudi Arabia | Asir | [42] |

| Vistra Moss Landing | 2021 Q2 – 2023 Q3 | 1800 (was 3000) | 450 (was 750) | 4 | Lithium-ion | United States | Moss Landing, California | [43][44][45] |

| Gemini | March 2024 | 1416 | 380 | 4 | Lithium-ion | United States | Clark County, Nevada | [46][47][48] |

| Crimson | October 2022 | 1400 | 350 | 4 | Lithium-ion | United States | Riverside County, California | [49] |

| Desert Peak Energy Storage I | July 2023 | 1300 | 325 | 4 | Lithium-ion | United States | Palm Springs, California | [50][51] |

| The Red Sea Project | 2024 | 1300 | Lithium-ion | Saudi Arabia | Tabuk province | Off-the-grid/microgrid[52][53][54] | ||

| Eleven Mile | 2024 | 1200 | 300 | 4 | USA | Pinal County | [55] | |

| Kenhardt | December 2023 | 1140 | 225 | 5 | South Africa | Northern Cape | [56] | |

| Oberon | November 2023 | 1000 | 250 | 4 | Lithium-ion | United States | Riverside County, California | [57][58] |

| Sonoran | March 2024 | 1000 | 260 | 4 | United States | Buckeye, Arizona | [59] | |

Under construction

| Name | Planned commissioning date | Energy (MWh) | Power (MW) | Duration (hours) | Type | Country | Location | Refs |

|---|---|---|---|---|---|---|---|---|

| Waratah Origin | 2025 | 1680 | 850 | 2 | Lithium-ion | Australia | [60][61][62] | |

| Melton Melbourne Renewable Energy Hub (MRHE) | 2026 | 1600 (800 in phase 1) | 800 (200 in phase 1) | 2 | Lithium-ion | Australia | [63][64] | |

| Collie Synergy | 2025 | 2000 | 500 | 4 | Australia | [65] | ||

| Collie Neoen | 2025 | 2000 | 500 | 4 | LFP | Australia | [66][67] | |

| South Pine Supernode | 2026 | 2000 (500 in stage 1) | 800 (250 in stage 1) | 2.5 | Australia | 27.319°S 152.968°E | [68] | |

| Eraring 1 | 2025 | 1700 (2800 in phase 2) | 460 (700 in phase 2) | 4 | Australia | 33°03′44″S 151°31′13″E | [69][70] | |

| Dengkou | 2025 | 1400 | 600 | 2.3 | LFP + vanadium flow | China | Bayannur | [71] |

| Víctor Jara (Oasis de Atacama) | 2025 | 1300 | LFP | Chile | Tarapacá Region | [72] | ||

| Quillagua (Oasis de Atacama) | 2025 | 1200 | 200 | 6 | LFP | Chile | María Elena | 221 MW solar[72] |

| Arena | 2026 | 1100 | 220 | 5 | Chile | [73] |

Planned

| Name | Planned commissioning date | Energy (MWh) | Power (MW) | Duration (hours) | Type | Country | Location | Refs |

|---|---|---|---|---|---|---|---|---|

| Ravenswood Energy Storage Project | 2024 | 2528 | 316 | 8 | Lithium-ion | United States | [74][75] | |

| Northern Gilboa | 3200 | 800 | 4 | Israel | [76][77] | |||

| CEP Energy, Kurri Kurri project | 2023[needs update] | 4800 | 1200 | 4 | Lithium-ion | Australia | [78][79] | |

| Green Turtle | 2800 | 700 | 4 | Belgium | Dilsen-Stokkem | [80] | ||

| Libra | 2027 | 2800 | 700 | 4 | Lithium-ion | USA | Yerington, Nevada | [81] |

| Energy Australia Jeeralang big battery | 2026 | 1400 | 350 | 4 | Lithium-ion | Australia | [82] | |

| Mufasa | 2026 | 1450 | 360 | 4 | Netherlands | Vlissingen | [83] | |

Market development and deployment

Summarize

Perspective

While the market for grid batteries is small compared to the other major form of grid storage, pumped hydroelectricity, it is growing very fast. For example, in the United States, the market for storage power plants in 2015 increased by 243% compared to 2014.[85] The 2021 price of a 60 MW / 240 MWh (4-hour) battery installation in the United States was US$379/usable kWh, or US$292/nameplate kWh, a 13% drop from 2020.[86][87]

In 2010, the United States had 59 MW of battery storage capacity from 7 battery power plants. This increased to 49 plants comprising 351 MW of capacity in 2015. In 2018, the capacity was 869 MW from 125 plants, capable of storing a maximum of 1,236 MWh of generated electricity. By the end of 2020, the battery storage capacity reached 1,756 MW.[88][89] At the end of 2021, the capacity grew to 4,588 MW.[90] In 2022, US capacity doubled to 9 GW / 25 GWh.[91] USA installed 12.3 GW and 37.1 GWh of batteries in 2024.[92]

As of May 2021, 1.3 GW of battery storage was operating in the United Kingdom, with 16 GW of projects in the pipeline potentially deployable over the next few years.[93] In 2022, UK capacity grew by 800 MWh, ending at 2.4 GW / 2.6 GWh.[94] In June 2024 the capacity was 4.6 GW of power and 5.9 GWh of energy.[95]

Europe added 1.9 GW in 2022, with several more projects planned.[96]

At the end of 2024, China had 62 GW / 141 GWh of battery power stations.[97] In 2020, China added 1,557 MW to its battery storage capacity, while storage facilities for photovoltaics projects accounting for 27% of the capacity,[98] to the total 3,269 MW of electrochemical energy storage capacity.[99]

Some developers are building storage systems from old batteries of electric cars, where costs can probably be halved compared to the original price.[100] A 53 MWh battery made from 900 electric cars started in 2024.[101]

See also

References

Wikiwand - on

Seamless Wikipedia browsing. On steroids.